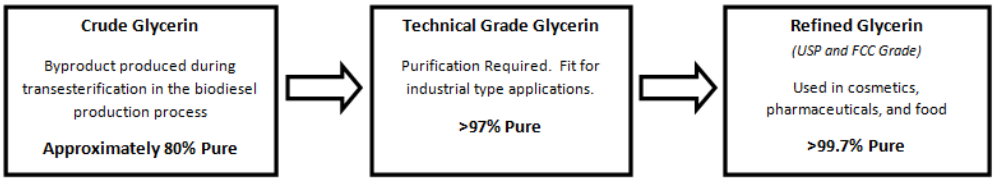

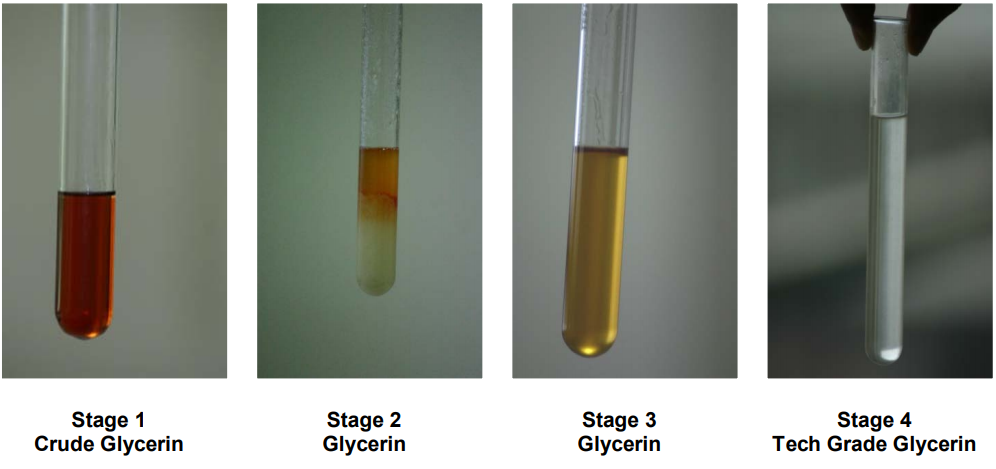

within the global market has created volatile pricing throughout the industry. The abundant supply of crude glycerin is a direct result of the increase in biodiesel production and without refinement, this impure form of glycerin must either be disposed of in a certain amount of time, according to the EPA, or it is sold off to market for a minimal amount due to the water, methanol, and salt content.

The current price volatility of glycerin, primarily brought on by biodiesel production, has resulted in tremendous changes in the glycerin refining sector. The demand for refined glycerin, technical grade and higher, has risen and is starting to stabilize. It is for this reason that we at SRS Engineering have focused much of our attention on glycerin refinement, helping biodiesel plants turn a stronger profit with their finished glycerin, thus avoiding high disposal fees or minimal returns from their crude glycerin. By further refining the glycerin to a >97% purity range, plants can now

sell off their glycerin for a much higher return and create a new profit center for their plant.

Disposing of crude glycerin can not only be costly but wasteful. Why not utilize all of your glycerin and turn a profit rather than paying high disposal fees or accept minimal payment for it? Incorporating SRS' high-purity glycerin purification system into your plant, can do just that. Because the system produces high-purity glycerin in high yield, there is no need for disposal of your glycerin since it now meets technical grade glycerin standards and can be sold to market for a higher profit. The system will actually take your crude glycerin with an approximate purity rating of 80% to a technical grade glycerin of >97%.

Technical grade glycerin provides multiple advantages to the biodiesel plant owner by:

- Eliminatingthe high cost of toxic waste disposal or if selling the glycerin, increasing the value of the end product (now a technical grade rather than crude)

- Freeingthe plant owner of potential EPA issues

- Creatinga new profit center for the plant

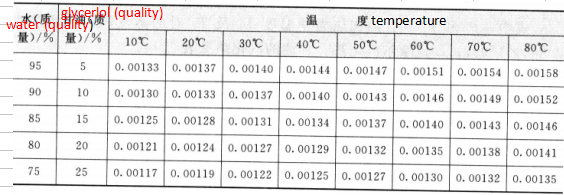

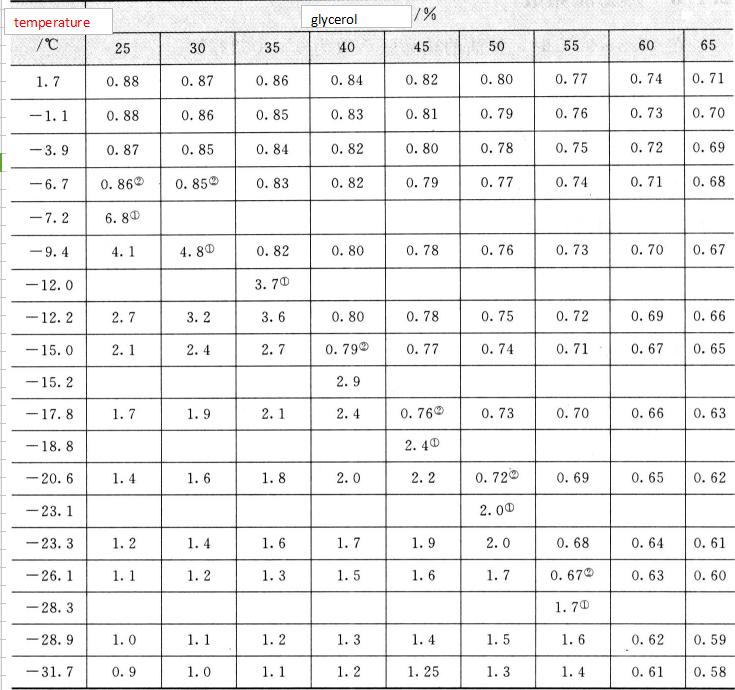

/(cal/(g.0C))

/(cal/(g.0C))