Glycerol (also known as glycerin) is a major byproduct in the biodiesel manufacturing process. In general, for every 100 pounds of biodiesel produced, approximately 10 pounds of crude glycerol are created. As the biodiesel industry is rapidly expanding, a glut of crude glycerol is being created. Because this glycerol is expensive to purify for use in the food, pharmaceutical, or cosmetics industries, biodiesel producers must seek alternative methods for its disposal. Various methods for disposal and utilization of this crude glycerol have been attempted, including combustion, composting, anaerobic digestion, animal feeds, and thermochemical/biological conversions to value-added products. The objective of this article is to provide a general background in terms of waste glycerol utilization.

Characterizations of Glycerol Waste

Crude glycerol generated from biodiesel production is impure and of little economic value. In general, glycerol makes up 65% to 85% (w/w) of the crude stream . The wide range of purity values can be attributed to different glycerol purification methods or different feedstocks used by biodiesel producers. For example, Thompson & He (2006) have characterized the glycerol produced from various biodiesel feedstocks. The authors found that mustard seed generated a lower level (62%) of glycerol, while soy oil had 67.8 % glycerol, and waste vegetable oil had the highest level (76.6 %) of glycerol.

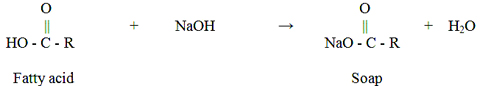

Methanol and free fatty acids (soaps) are the two major impurities contained in crude glycerol . The existence of methanol is due to the fact that biodiesel producers use excess methanol to drive the chemical transesterification to completion, and do not recover all the methanol. The soaps, which are soluble in the glycerol layer, originate from a reaction between the free fatty acids present in the initial feedstock and the catalyst (base).i.e.,

In addition to methanol and soaps, crude glycerol also contains a variety of elements such as calcium, magnesium, phosphorous, or sulfur. Thompson & He (2006) reported that the elements present in the glycerol of different feedstock sources (such as canola, rapeseed, and soybean) were similar. Calcium was in the range of 3-15 ppm, magnesium was 1-2 ppm, phosphorous was 8-13 ppm, and sulfur was 22-26 ppm. However, when crambe (a perennial oilseed plant) was used as feedstock, crude glycerol contained the same elements, but at vastly different concentrations. Schröder & Südekum (1999) also reported the elemental composition of crude glycerol from rapeseed oil feedstock. Phosphorous was found to be between 1.05 % and 2.36 % (w/w) of the crude glycerol. Potassium was between 2.20 % and 2.33%, while sodium was between 0.09% and 0.11%. Cadmium, mercury, and arsenic were all below detectable limits.

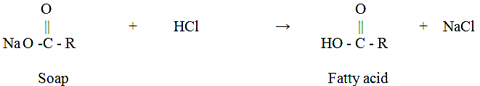

The crude glycerol derived from alkali-catalyzed transesterification usually has a dark brown color with a high pH (11-12). When pH is adjusted to a neutral range, soaps will be converted into free fatty acids, as shown in the following equation

The free fatty acids in the crude glycerol stream results in a cloudy solution. After settling for a period of time, this cloudy solution will be separated into two clear phases, with the top layer being the free fatty acid phase, and bottom layer the glycerol phase.

No comments:

Post a Comment